Ethan R. Brush

Energy, Environmental, Transportation |

Market Co-Leader

Principal

Methods for storing energy have been employed for decades in the form of pumped hydroelectric reservoirs, compressed air, or via thermal energy transfer.

Methods for storing energy have been employed for decades in the form of pumped hydroelectric reservoirs, compressed air, or via thermal energy transfer. Today we can store enough energy in a chemical battery to supply power to an entire community. Battery energy storage systems, often referred to as “BESS”, promise to be critically important for building resilient, reliable, and affordable electricity grids that can handle the variable nature of renewable energy sources like wind and solar. They also offer almost instantaneous peak shaving, load shifting, and megawatt scale emergency backup power functions that are currently provided primarily by fossil fuel systems. BESS may prove key in supporting data centers, with rising power demands and calls from the community to meet sustainability goals. These are important advancements for today’s electrical grid and will continue to play a key role in ensuring communities are powered by green energy, even when the sun isn’t shining or when the wind has stopped blowing.

The many benefits of battery energy storage systems, and the ability for them to be deployed in a relatively small footprint – only getting smaller as energy density increases – means that we may soon be seeing them everywhere. Like solar and wind energy sites, Acentech is positioned to be a national resource for mitigating the noise from BESS installations so that they can be properly sited per local regulations, and to reduce the risk of community annoyance. BESS sound is of particular importance because these stations are located within communities very close to residential properties.

You might be thinking “what makes sound at a battery energy storage facility?” The main noise sources from a BESS facility are:

Cooling systems

Like any electronic device, grid-scale battery systems operate most optimally and safely at an ideal temperature and humidity. Therefore, various air or liquid cooling and heating systems are used. Sound from inlet and outlet airflow vents, as well as fans and pumps are emitted from each battery enclosure. The sounds from these systems are similar to rooftop heating ventilation and cooling units in residential and commercial buildings.

Inverters

Inverters convert electricity from direct current (DC) in the batteries to alternating current (AC) that we use in our homes. The process also happens in reverse when AC electricity is used to charge the batteries. A small amount of energy is lost in the form of heat with this conversion, so cooling is needed to prevent overheating. This is usually accomplished with air-cooled fans that produce some noise.

The process of converting DC into AC power requires very fast switches which change the polarity (or direction of electrical flow). In the United States AC power cycles 60 times per second (or 60 hertz), so the switches must activate twice per electrical cycle. This process produces tonal sound at twice the electrical line frequency (120 hertz), as well as its harmonics (240, 360, 480 hertz and higher). The nature of this sound is typically heard as a buzz.

Transformers

Transformers are used to change AC voltages to step up or step down in level. Everyone should be familiar with the cylindrical transformers on telephone poles that lower the voltage from the high voltage transmission lines to a level that is safe for use in homes and businesses. The transformers at a BESS facility are much larger than those you see on telephone poles. There are three sources of noise from within the transformer: (1) core noise, (2) coil noise, and (3) fan noise. The core and coil noise are caused by electromagnetic forces which occur two times for every cycle of AC power. Like the inverters, this results in a 120-hertz primary sound source, along with its harmonics. The third source of sound is from cooling fans mounted outside the transformer.

The sound that most people think of from transformers is a distinctive “hum”. If you’ve ever been around an outdoor substation or a building’s transformer vault, you may be familiar with this sound. If not, then you can give this video a listen.

As with many emerging technologies, there is limited data on the amount of sound produced by the newest products. A single BESS project could have many different suppliers, which can make accurate modeling of the total facility noise levels challenging if there is missing information. Various standards from organizations like NEMA, IEC, IEEE, AHRI, ASHRAE, ANSI, and ISO provide guidelines for quantifying sound emissions from BESS equipment.

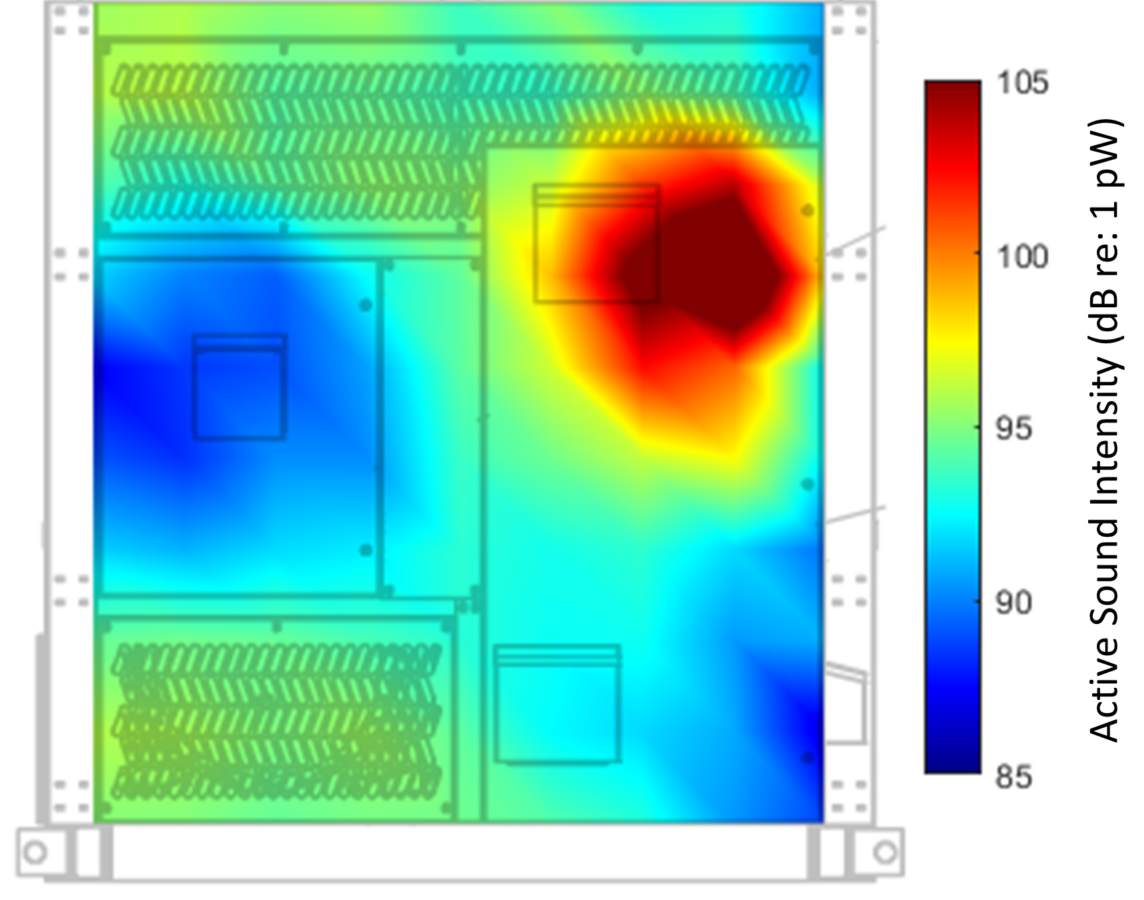

Acentech has invested in technology and methods to obtain very detailed sound power measurements for a range of equipment, including BESS products. A sound intensity probe is used to measure the acoustic sound power per unit area over a grid surrounding the item under test. This method allows us to see where the dominant noise sources are located, as shown in the figure below, allowing us to provide more targeted noise control options. For example, if the dominant sound is coming from lower on the equipment, then this may allow for shorter, and less costly/intrusive noise barriers surrounding the installation.

While BESS facilities are relatively new developments, each of these noise sources are common among many other industries that have been around for a very long time. Therefore, we have the tools necessary to design a BESS facility with the right noise control treatments so that it can be a good noise neighbor, just like any other industrial facility. To do that, we generally follow these steps:

Model the sound from the BESS facility to the community

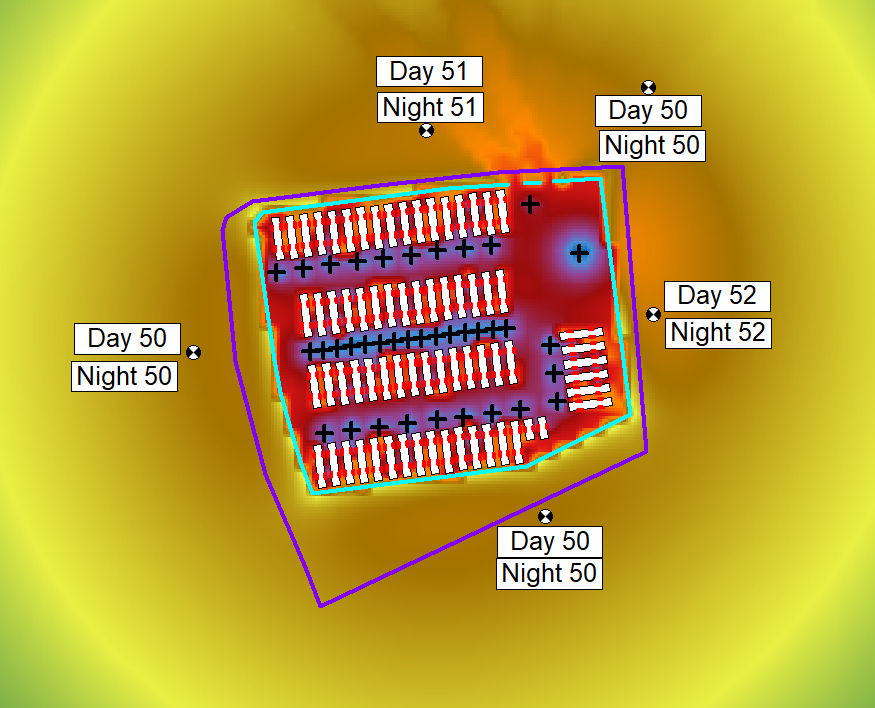

During the design process for a BESS facility, Acentech will identify all of the significant sound sources from the various equipment. Ideally, vendors should provide information regarding their product’s noise emissions. However, this information isn’t always available from vendors, so it must be obtained from field measurements at existing installations, or from the detailed measurements from Acentech shown above. The equipment noise data will be used to generate a model of the total facility’s sound emitted at the property line and at sensitive receptors such as homes. The model includes all necessary equipment sound sources along with topographical features of the surrounding area. The results of this modeling evaluation will be compared to relevant noise limits for the project. The results of an example BESS sound modeling analysis are shown in the figure below.

Measure the site ambient sound levels

Many noise ordinances, such as the Massachusetts Department of Environmental Protection’s noise policy, stipulate that the facility sound levels must not exceed a threshold above ambient conditions. Those ambient sound levels need to be established before the project is installed, or during a time when the facility is completely shut down. At Acentech, we will typically measure ambient sound conditions for a week or more during relatively calm weather to obtain a full characterization of the sound environment at a site. Because the noise limits are relative to the ambient site conditions, a quiet area will require a lower limit than an already noisy area.

Noise ordinances in other places often prescribe a fixed limit for the amount of noise that may be produced. This may not necessarily need a site study for demonstrating compliance, but ambient noise measurements are usually recommended to help put the results of modeling efforts into context of the existing environment.

Add noise control measures

Designing noise control measures for a BESS facility is an iterative process. If the initial design and layout of the noise producing equipment is expected to exceed the relevant noise limits for the project, then we will offer suggestions to lower the predicted sound emissions from the total facility.

Sometimes the easiest mitigation is to simply move the loudest noise sources farther away from the nearest property line or sensitive receptor. However, BESS facilities often place multiple large battery systems in a grid in order to fit as many of them in an area as possible. Sound enclosures may be considered for some equipment, but the most common form of noise control is a noise barrier of appropriate height. Noise barrier walls block the direct path of noise from the source to the sensitive receptor. Orientation of the BESS unit equipment within the grid of systems can also be considered so that the loudest equipment faces away from a sensitive receptor.

These mitigations are then added to the acoustical model of the facility and surrounding area. The process is complete when the predicted sound levels are compliant with the relevant noise limits for the project.

Post construction sound measurements

Sometimes it is appropriate to measure the sound levels at sensitive receptors after a facility is fully completed to demonstrate compliance with noise ordinances. This is typically done at night when the ambient sound is at a minimum and may include turning all BESS equipment on and off for periods of time to fully characterize the total facility sound emissions.

When planning for a battery energy storage site, it is important to enlist the help of acoustical consultants to navigate the regulatory process surrounding noise and ensure the right noise controls are implemented. With a thoughtful approach and effective noise control treatments, battery energy storage system facilities can continue to be added to our electrical grid without causing undue noise for anyone living close by.