Alex Odom

Associate Principal

Halloween is approaching and our “spider senses” are tingling at Acentech. Spiders share one thing with acoustical consultants: we are both on the lookout for vibrations. Webs woven from spider silk are feats of arachnid engineering, designed to trap prey and transmit the vibration of their movements so the spiders can find them.

At Acentech, while we don’t have spider senses, we do have access to a wide range of sensors to measure vibration in buildings. Accelerometers – which measure the acceleration of a vibrating surface – are by far the most common type of vibration sensor employed at Acentech. While measuring vibration in an existing building is relatively straightforward, the most challenging part of our work is predicting vibration in a building before it is built.

Predicting Building Vibration

In our analyses, we typically consider three principal sources of vibration:

1) environmental vibration (the vibrations that enter the building from outside)

2) building systems (such as mechanical equipment), and

3) human activity.

Typical environmental vibration sources include rail lines, highways and roads, and industrial facilities. Often, the best approach in limiting these vibrations is to locate the facility suitably far from the environmental vibration source.

Building systems include the mechanical, electrical, and plumbing infrastructure required to support the building. These systems are often located inside the building and are best addressed by way of well‑conceived and effective vibration isolation systems.

The final principal source of vibration is human activity, such as fitness activities in some mixed-use developments, or the source found in all occupied buildings: people walking.

Although you might not expect it, human activity (people walking) is often the greatest source of floor vibration on above-grade floors in buildings. Similar to the way that a spider’s web will shake because of the movements of trapped insects, above-grade floors move in response to a footstep impulse. The vibration is strongest at a particular frequency – the natural frequency – much the same way a guitar string responds to being plucked. The guitar’s note is determined by the mechanical properties of the string, whereas the floor response depends on the floor’s stiffness and mass.

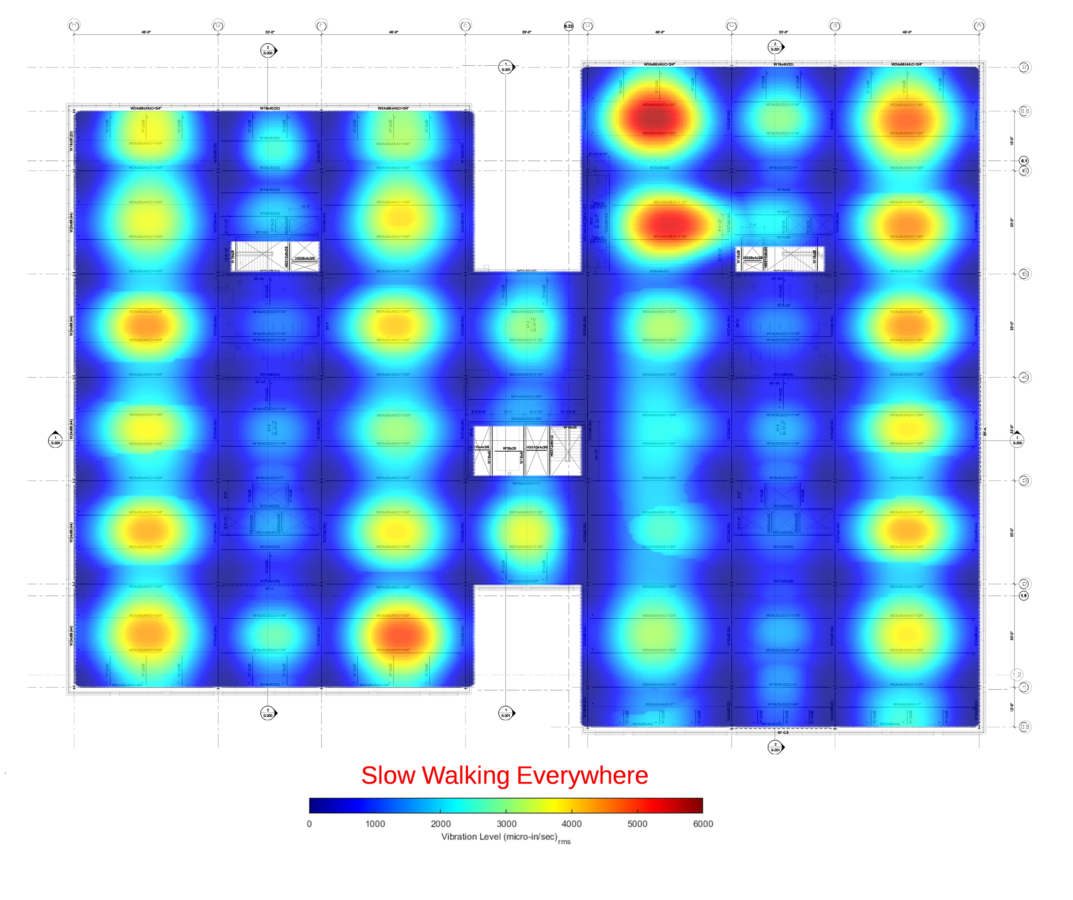

Vibrations due to footfalls depend on where the walking occurs and how fast-paced it is. Generally, vibrations increase with walker speed. We normally consider four walking scenarios: very slow walking (75 steps/min), slow walking (96 steps/min), moderate walking (111 steps/min), and fast walking (126 steps/min). For core and shell projects where we do not know the final layout of corridors, we typically consider very slow and slow-paced walking everywhere, and fast walking in potential corridor areas. Footfall-induced vibrations are generally highest at the middle of structural bays and lowest near columns where the floor is naturally stiffer. When possible, corridors and sensitive equipment should be placed as close as possible to the stiffer parts of the floor near columns, or along column lines.

To help architects make space-planning decisions on where to locate vibration-sensitive equipment, we can predict the vibration from walking in different areas of the building. Following the methods in the 2nd Edition of the American Institute of Steel Construction (AISC) Design Guide 11, we create a finite element model of a building structure to calculate its dynamic properties. The response of the floor to an input force includes a summation of many different natural frequencies and mode shapes exhibited by the building structure. This information is used to predict footfall vibration across an entire floor plate, as shown in this “heat map” graphic below.

Reducing Building Vibration

If our predictions suggest that footfall-induced vibrations are too high, reasonable changes to the structural design can usually be made. To a good approximation, footfall-induced vibrations are inversely proportional to the bay stiffness and structural damping (the amount of energy dissipated through the structure). In order to decrease vibration, the bay stiffness must increase. Stiffer bays also have a higher natural frequency that is less excited by walking. Where it is not feasible to reduce the vibration enough through structural changes, sensitive equipment can often be protected locally by way of commercial vibration isolation systems.

Whatever the solution, Acentech can help ensure that even the most sensitive lab equipment does not fall prey to the disquieting vibrations of back-to-office walkers!